Why is Reliability Engineering Important?

Reliability engineering is a cornerstone discipline that ensures products, systems, and services operate as intended for their intended lifespan.

This comprehensive field plays a pivotal role in numerous industries, contributing to better safety, cost-effectiveness, enhanced productivity, customer satisfaction, and adherence to regulations.

In this article, we will look into the profound significance of reliability engineering and its impact on business success.

Table of Contents

The Importance of Reliability Engineering

1. Improving Safety

Reliability engineering serves as a safeguard against catastrophic failures. In industries where human lives are at stake, like aviation and medical devices, reliable products are essential.

Consider an aircraft: A reliable one is less likely to crash, instilling confidence in passengers and airline companies alike.

Similarly, medical devices, such as life-support systems, must function without fail to prevent harm to patients.

2. Reducing Costs

Reliable products and systems require fewer maintenance and repair interventions, translating into substantial cost savings for businesses.

Think about a reliable car; it demands fewer repairs compared to an unreliable counterpart.

The same principle applies to industries like energy, where a reliable power plant requires less maintenance than an unreliable one, minimizing downtime and costs.

3. Increasing Productivity

Operational efficiency is a hallmark of reliability engineering. When products and systems operate reliably, they contribute to enhanced productivity.

A reliable factory machine, for instance, can churn out more products per hour than an unreliable one.

This efficiency boost directly impacts the bottom line and overall business success.

4. Enhancing Customer Satisfaction

Customers are naturally drawn to products and services they can rely on. Reliability fosters customer satisfaction, which, in turn, leads to increased sales and higher profits.

Imagine a customer purchasing a new car and experiencing minimal issues over time; they’re more likely to become brand advocates and recommend the product to others.

5. Regulatory Compliance

Numerous industries are subject to stringent regulations that demand adherence to specific reliability standards.

For instance, the aviation industry operates under strict regulations governing aircraft reliability.

Compliance is crucial not only for ensuring safety, but also for avoiding legal repercussions and maintaining the integrity of the industry.

Key Features of Reliability Engineering

a) Failure Analysis

Failure analysis is at the core of reliability engineering. By identifying the root causes of failures, engineers can develop strategies to prevent similar issues in the future.

This proactive approach not only enhances product performance but also contributes to long-term cost savings.

b) Risk Assessment

Reliability engineering involves quantifying risks associated with potential failures.

This information helps prioritize preventive measures, ensuring that resources are directed where they are most needed.

Effective risk assessment minimizes surprises and contributes to a well-structured risk management strategy.

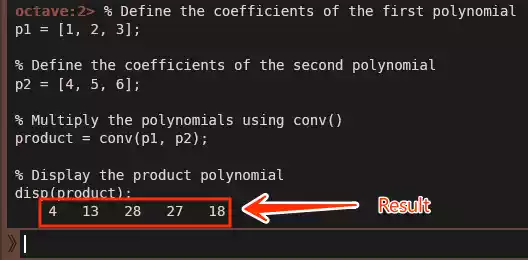

c) Probabilistic Modeling

Probabilistic modeling leverages mathematical models to predict the likelihood of failure.

These predictions inform decision-making processes regarding design, maintenance, and testing strategies.

By quantifying potential failures, businesses can allocate resources more effectively and make informed choices.

d) Life Cycle Management

Reliability engineering extends throughout the entire life cycle of a product or system.

From design to disposal, engineers engage in activities such as reliability testing, maintenance planning, and failure data analysis.

This comprehensive approach ensures optimal performance and longevity.

Wrap Up

As a wrap up, Reliability Engineering stands as the bedrock of success, championing safety, cost-effectiveness, productivity, customer contentment, and adherence to regulations.

Its firm commitment to ensuring products operate flawlessly is the anchor of achievement across diverse industries.

FAQs about Reliability Engineering

- What is the primary goal of reliability engineering? Reliability engineering aims to ensure that products, systems, and services function as intended for their intended duration, enhancing safety, efficiency, and customer satisfaction.

- How does reliability engineering impact safety? Reliability engineering prevents catastrophic failures, reducing the likelihood of accidents and injuries. It instills trust in industries where safety is paramount.

- Is reliability engineering relevant across all industries? Yes, reliability engineering is applicable across various industries, including aviation, healthcare, manufacturing, energy, and more.

- Can reliability engineering reduce operational costs? Absolutely. Reliable products require fewer repairs and maintenance, resulting in substantial cost savings over time.

- How does reliability engineering contribute to regulatory compliance? Reliability engineering ensures products and systems meet stringent regulatory standards, preventing legal issues and maintaining industry integrity.

- What is the role of risk assessment in reliability engineering? Risk assessment quantifies potential failure risks, enabling prioritization of preventive measures and informed resource allocation.